Sert Lehimleme #Brazing

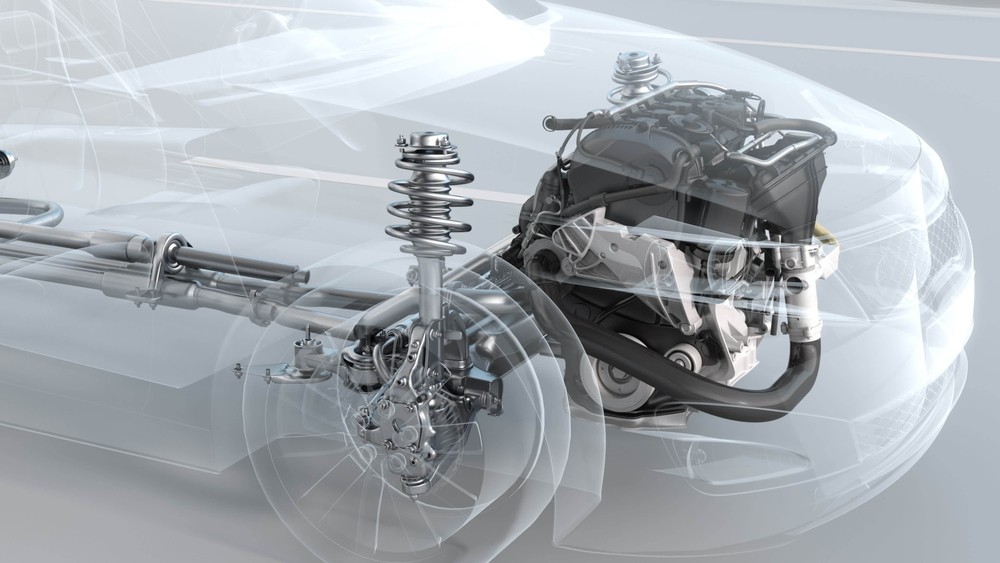

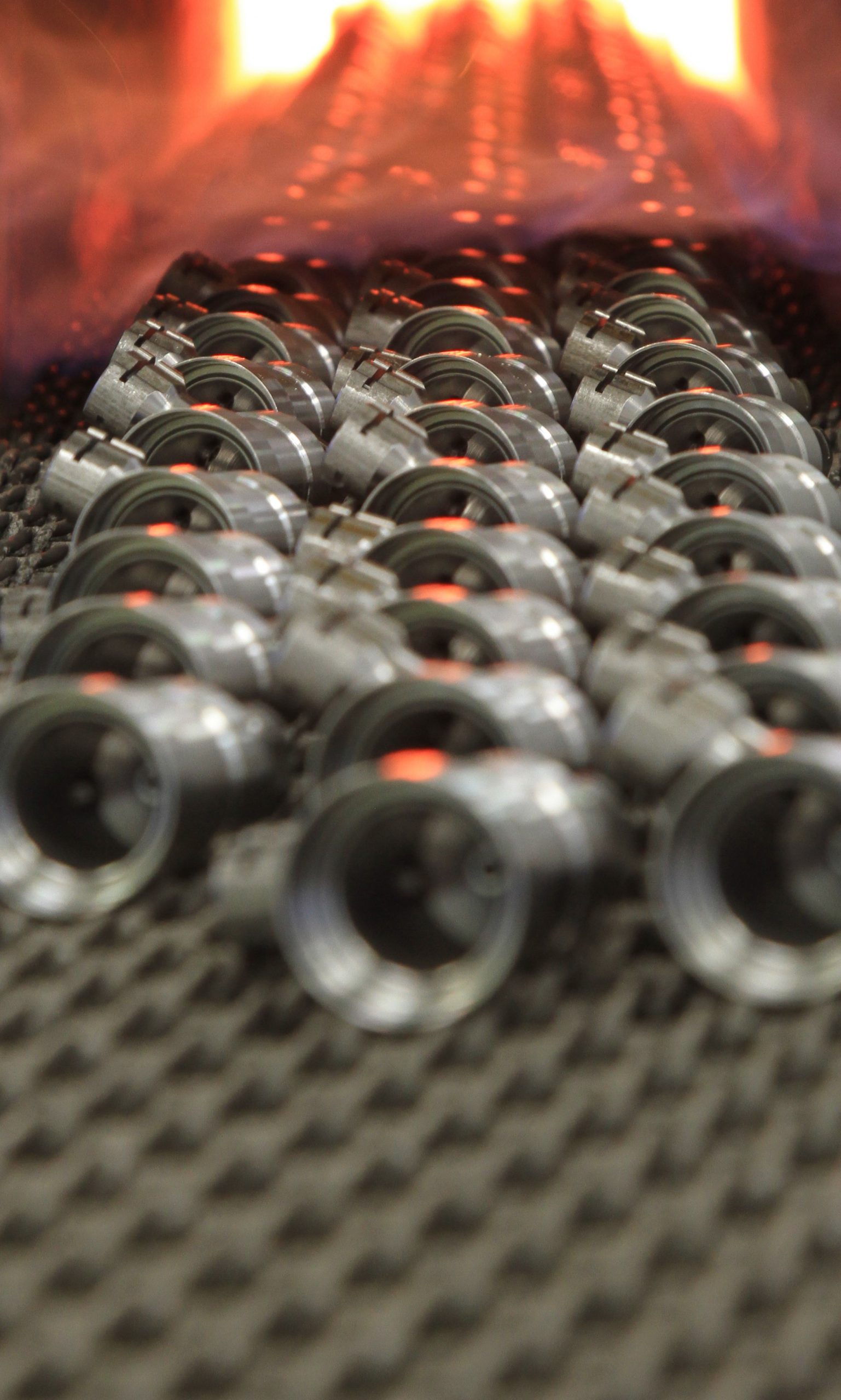

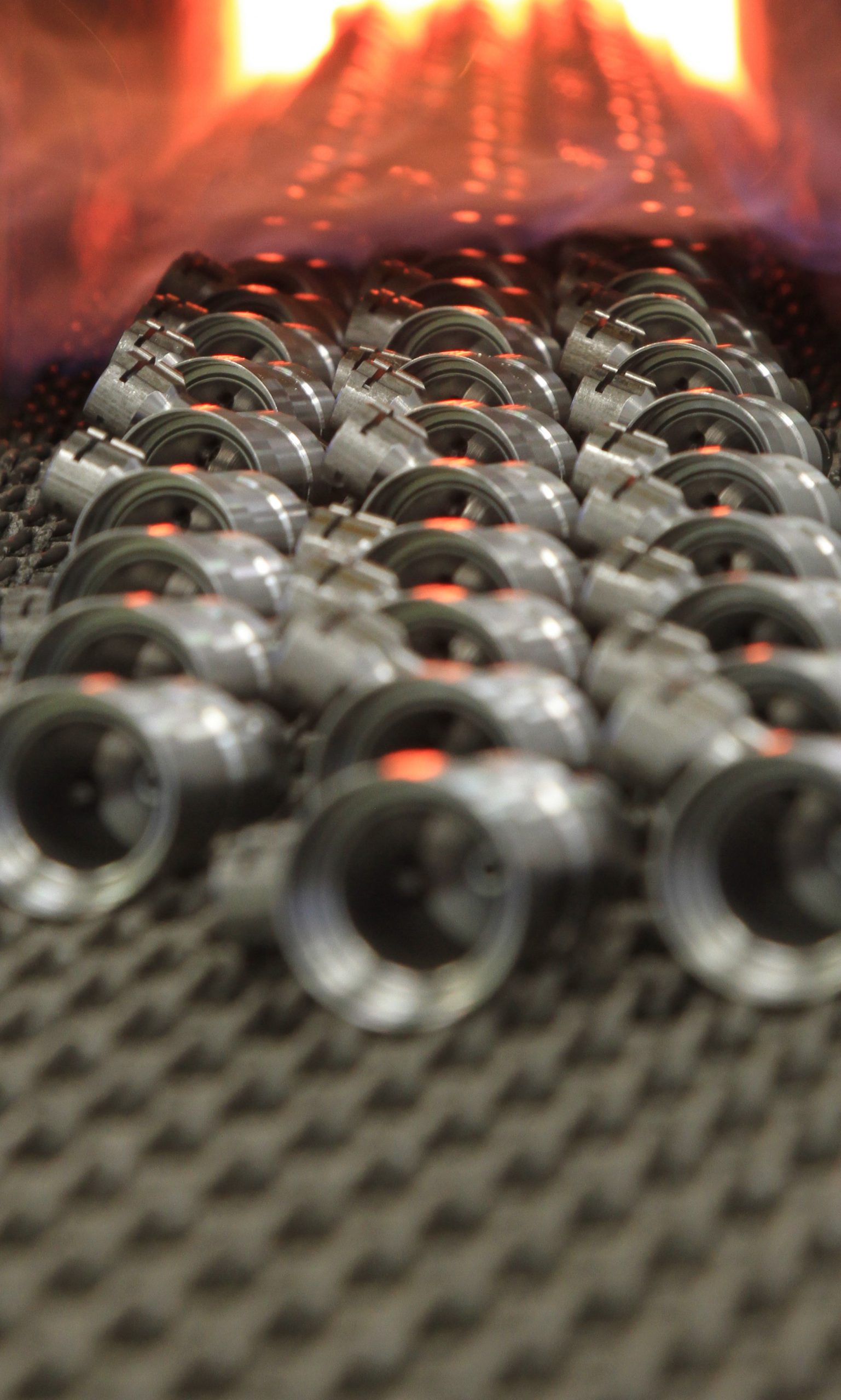

Otomotivde, özellikle içinden akışkan hava, yakıt, su veya hidrolik yağ geçen çelik boru ve parçaların birleştirilmesinde en etkili yöntem sert lehim veya brazing kaynağıdır. Bakır ve alaşımlarının birleştirici lehim malzemesi olarak çok kullanıldığı sert lehim (brazing) fırınlarında birleştirilecek parçalar sıkı geçme olarak verilir.

Taşıyıcı bant yardımı ile koruyucu gaz ortamındaki fırına giren parçalar ön ısıtmadan sonra, kullanılan lehim malzemesinin cinsine göre 1100 °C sıcaklığa kadar ısıtılarak lehim malzemesinin ergimesi sağlanır. Koruyucu gaz atmosferinde oksidasyon olmayan ortamda ergiyen lehim malzemesi “capilar” kuvvetlerin etkisi ile parçaların birleşme yerine hızla nüfus eder. Lehimlenmiş parça yine koruyucu atmosfer ortamında ilerleyerek soğutma tünelinde geçtikten sonra mükemmel birleşme ve yüzey kalitesinde tünel çıkışından alınır.

EN

EN  FR

FR